When it comes to maintaining a workplace that is both OSHA compliant and safe for your employees, one of the main things to consider is electric safety. Faulty electric systems could result in the loss of equipment, injury to workers, hefty fines, and a significant blow to your company's reputation. When you are evaluating the safety level of your worksite, one potential risk to be aware of is ground faults. But what are ground faults, and how can you prevent them at your workplace?

Ground Fault Definition

Before we can define a ground fault, we should quickly specify a fault in general. Any type of electrical fault is, essentially, an abnormal flow of electricity. Electricity is intended to stay within its electrical current, and when the electricity goes astray, a fault occurs. A ground fault occurs when the electrical current strays from its path and flows directly into the ground, hence the name.

Ground Fault vs. Short Circuit

If you are familiar with what a short circuit is, you may notice that its definition is incredibly similar to that of a ground fault. Technically, a ground fault is a type of short circuit. Most experts agree that the main distinction between a ground fault and a short circuit is the surface that the conductor is making contact with.

In a short circuit, an energized conductor comes into contact with another conductor (think sticking a metal fork into a toaster) or the ground. A ground fault, as the name suggests, can only be classified as such when that energized conductor meets the ground. The electric current could travel directly into the ground or through a grounded portion of a system, like a metal electrical box.

Dangers of Ground Faults

The most obvious danger of ground faults is electric shock, which can cause damage or injury to both property and people. On your work site, a ground fault could result in your equipment being damaged or even destroyed, and any employees working in the area could be at risk of injury or even death.

Since ground faults bring the electric current directly to the ground, any worker standing in the area is in danger. Ground faults can be particularly dangerous if the ground is damp, since the water can move the electric current extremely quickly.

On top of the potential danger to workers and equipment, ground faults could have a severe negative impact on your business as a whole. If a ground fault occurs on your worksite and OSHA determines that you or negligent in protecting your workers or performing preventative maintenance to prevent the situation, you could find yourself paying a hefty fine. Additionally, getting bad news from OSHA could impact the reputation of your company, causing you to lose customers or prevent talented employees from working for you.

Causes of Ground Faults

As we mentioned, water is a major conductor of electricity and is a particular danger in the case of a ground fault. So, one of the most common causes of ground faults is water leaking in the area or into an electrical box.

Additionally, hot wires that are loose or worn could potentially cause a ground fault. These wires are not secured as they should be, giving them the chance to come into contact with a grounding device or ground wires.

Employees working with an electric circuit may be at risk of a ground fault if their power tools or appliances don't have the proper insulation. We’ll touch more on this in a moment, but GFCI outlets or extension cords should always be used to ensure your power tools are operating safely.

Other potential causes of ground faults could include pest damage to your electrical system, improper wiring of an outlet, and decayed insulation.

How to Prevent Ground Faults

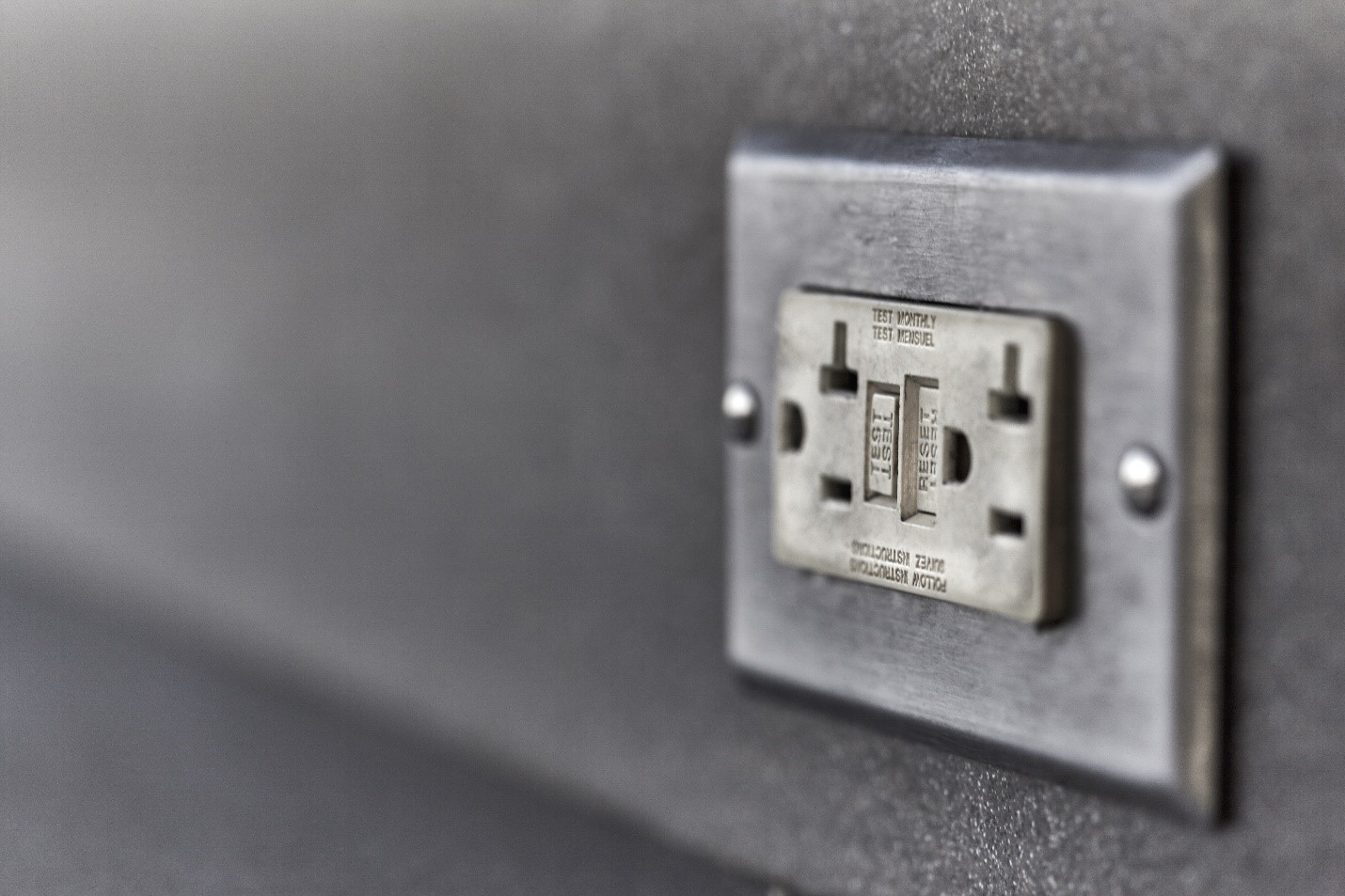

Now that you know about what causes ground faults, how can you prevent them? One of the easiest and most effective ways to prevent ground faults is by utilizing GFCI outlets and circuit breakers. GFCI stands for ground fault circuit interrupter, and the name is quite self-explanatory. When this type of outlet or circuit breaker senses that there is an imbalance between the incoming and outgoing currents, they will automatically shut off the electric power to prevent injury or property damage. GFCI outlets can be installed yourself, or you can ask your electrician to install them for you.

It also helps to bring in an electrician or electrical engineer regularly for preventative maintenance and to ensure that your electrical systems are wired and operating as they should be. If your electrical engineer notices that the wiring is damaged, they will be able to replace it to reduce your risk of a ground fault or other electrical emergency. Electrical engineers can also test your GFCI circuit breakers to make sure they’re ready to act in the case of a ground fault.

If you notice that appliances within your workplace cause a shock when you touch them or your GFCI circuit breaker trips frequently, be sure to bring in an engineer. They will be able to fix the problem or recommend that you replace your appliance or breaker.

Electrical Services from MTAEE

For preventative maintenance to protect your business from ground faults, short circuits, and other electrical hazards, turn to a group of professionals like MTA Electrical Engineers. Our electrical testing service helps ensure your workplace is safe and compliant with the latest IEEE, NEC, and NFPA standards. Not only will our experienced technicians check your grounding systems, ground fault systems, and circuit breakers, but they can also check your cables, transformers, motor control center, switchgear, and more.

We are happy to also offer Power System Evaluations to help you ensure the reliability and cost-effectiveness of your system. In addition to these two popular services, we also offer Arc Flash Analyses, Coordination Studies, Electrical Drawings, Short Circuit Analyses, and more. MTAEE is proud to serve a wide range of clients located throughout San Diego, Los Angeles, and all of Southern California. To learn more about how MTAEE can help you ensure the electrical safety of your workspace, contact us today!