Arc flash incidents can be catastrophic, posing severe risks to both employees and equipment. To mitigate these dangers, regulations require employers to implement safety measures, including the use of arc flash labels. This article will explore the necessity of arc flash labels, delve into employer requirements for protecting employees, and examine the key elements found on an arc flash label.

Are Arc Flash Labels Required?

Yes, arc flash labels are indeed required, and their importance cannot be overstated. It’s essential that you warn people that an arc may exist when interacting with electrical equipment.

Arc flash labels play a vital role in electrical safety programs, serving as a crucial means of informing employees about potential arc flash hazards associated with electrical equipment. Regulatory bodies, including the United States' Occupational Safety and Health Administration (OSHA) and various international safety standards, mandate the use of these labels.

According to NFPA 70E, labeling is required for any piece of electrical equipment that may need examination, adjustment, service, or maintenance while energized. Arc flash studies need to be reviewed/updated every 5 years or whenever there is a modification to THE electrical system. Failure to comply with these requirements can result in penalties and, more important, can endanger the lives of workers.

Employer Requirements for Arc Flash Safety:

- Develop an Arc Flash Hazard Analysis: Employers are obligated to perform an arc flash hazard analysis. This process involves assessing the electrical system to determine potential arc flash hazards and calculating the incident energy levels. The results of this analysis help in setting safe work practices and selecting appropriate personal protective equipment (PPE) for employees.

- Provide Proper PPE: Once the arc flash hazard analysis is complete, employers must provide suitable PPE to protect employees from potential arc flash incidents. PPE can include arc flash hoods, gloves, bibs, coveralls, and more, depending on the level OF PROTECTION needed.

- Establish Safe Work Practices: Employers must establish and enforce safe work practices, which include specific procedures for working on electrical equipment and systems. These practices should be based on the results of the arc flash hazard analysis and are vital for minimizing risks during maintenance or troubleshooting tasks.

- Offer Comprehensive Training: Adequate training is crucial for employee safety. Employers must ensure that workers are trained in electrical safety, hazard recognition, and the proper use of PPE. Regular refresher training is also necessary to keep employees informed and up-to-date on safety procedures.

- Use Insulated Tools: Another essential component of arc flash safety is the use of insulated tools. Employers should mandate the use of tools designed to prevent electrical contact and reduce the risk of arc flashes. These tools should be in good condition and regularly inspected to ensure their effectiveness in maintaining a safe work environment.

Who is Responsible for the Labeling?

In accordance with OSHA regulations, the duty of equipment labeling rests with the employer. More precisely, it is the employer's obligation to guarantee that all electrical equipment is affixed with suitable warning labels that communicate the potential hazards linked to the equipment. Additionally, employers are tasked with ensuring the longevity and legibility of these labels throughout their usage.

Guidelines for Compliant Placement of Arc Flash Labels

To stay compliant with OSHA regulations, arc flash labels should be strategically positioned on electrical equipment to ensure visibility.

Arc flash labels should be affixed to specific locations for optimal safety communication. These locations include the front cover of the equipment, the exterior of the equipment enclosure, the breaker door of a switchboard or panelboard, and the external surface of the control cabinet for an industrial control panel.

Placing arc flash labels in these areas ensures that essential safety information is easily accessible, promoting a safer working environment.

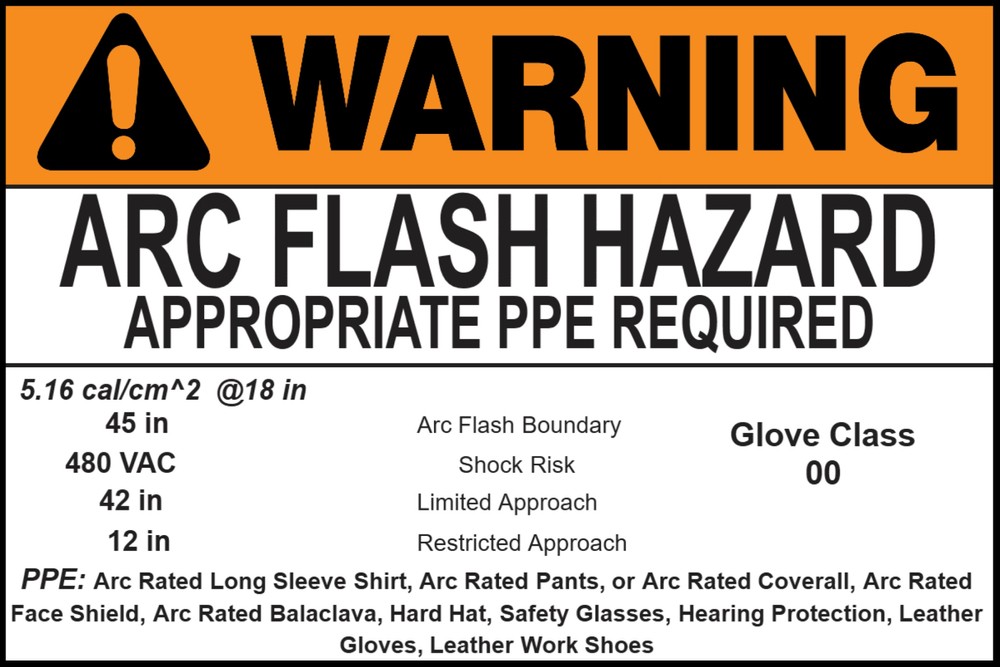

Key Elements of an Arc Flash Label:

Arc flash labels provide essential information to those working on or near electrical equipment. Here are the key elements commonly found on an arc flash label:

- Nominal System Voltage: This element specifies the voltage level of the electrical system. Understanding the nominal system voltage is crucial for assessing the potential arc flash hazard associated with the equipment in question.

- Arc Flash Boundary: The arc flash boundary establishes a minimum safe distance from the equipment at which employees must wear the designated PPE. It is demarcated (is there another word we can use for demarcated?) with a specific distance value to ensure workers maintain a safe buffer zone.

- Incident Energy: Measured in calories per square centimeter (cal/cm²), incident energy represents the thermal energy released during an arc flash event. This numerical value aids in the selection of appropriate PPE, ensuring that employees have adequate protection against thermal hazards.

- Arc Flash Hazard Level: The hazard level is typically conveyed through terms like "Danger" or "Warning" and provides a quick visual cue regarding the severity of the arc flash hazard. This element helps individuals quickly assess the potential risks associated with the equipment.

- Equipment Label: Detailed information about the specific equipment being labeled is essential for quick identification. This includes the equipment's location within the facility and a unique identifier that aids in tracking and maintenance.

- Label Update Date: The date of the most recent label update is a critical element in keeping the label current and accurate. Regular updates ensure that the information on the label reflects any changes in the electrical system or equipment configuration, providing employees with up-to-date safety information.

Incorporating these key elements on arc flash labels enhances workplace safety by providing clear, concise, and actionable information. It empowers employees to make informed decisions about their safety and helps employers comply with regulatory requirements.

Arc flash labels play a crucial role in ensuring the safety of employees working with electrical equipment. They are not only required by regulations but are also a fundamental part of any comprehensive electrical safety program. Employers must take the initiative to conduct arc flash hazard analyses, provide suitable PPE, establish safe work practices, and offer proper training to protect their workforce from the potentially devastating consequences of arc flash incidents. By understanding the elements on an arc flash label and adhering to these requirements, employers can create a safer working environment for all.

For expert guidance on arc flash safety and compliance, or to schedule an arc flash analysis for your building’s electrical system in California, contact MTA today and explore the resources on our site to keep your workplace safe. Your safety is our priority.